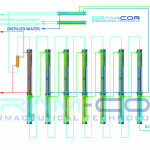

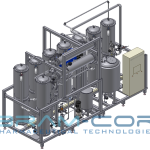

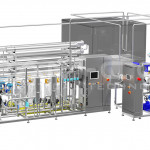

Every Bram-Cor SMPT – Multiple Effect Distiller is designed and manufactured according to cGMP and produced compendial Water for Injection. Each unit contains a number of boiling columns (or effects, stills) with the first column producing pure steam, which is condensed and re-distilled in the following columns decreasing the operational costs.

Heating for evaporation and cooling for condensation processes are performed by DTS (double tube sheet) exchangers. Condensation is achieved by means of the thin-falling film technology. The Multi Effect distillation process is repeated in each column: the higher the quantity of columns the lower overall the consumption of the equipment. The quantity of columns therefore does not influence the quality nor the output of the equipment. A special labyrinth-separator installed at the top of each column separates the steam generated by the evaporation process from entrained substance in the steam itself. The result is a pure, “dry”, pyrogen-free steam, condensed in compendial Water for Injection.

The first column of the Still may be used to produce alternatively or even at same time, also Clean Steam. Pressure vessels are designed according to PED regulation; the SMPT equipment features:

- Double tube sheet heath exchangers

- Certified AISI 316L stainless steel mirror-polished and passivated product contact surfaces

- AISI 304 frame, jackets and control board

- PTFE gaskets

- Pneumatic valves with Teflon membranes and AISI 316 L SS polished body

- ASTM C-795 – compliant insulation.

Capacities range: from 50 to 15.000 mph (from three to eight columns).

For more info about Bram-Cor MED systems, see multiple-effect-water-distiller.com

Click here to see (main Bram-Cor site) all the pharmaceutical lines (turnkey, water treatment, processing, filling and packaging systems).

© Bram-Cor SpA 2024